WELDER’S VIEW – January 21, 2019

Matt Cook from Meticulous Metal Works continued to help make the Switchblade prototype flight-ready. Above, he is shown welding on radiator tabs in the final position so we can finish the radiator installation. We had done paper ducts to sort out the shape and fit of the radiator ducts and radiators earlier. With these in place we saw how we would like to modify the radiator positioning so that we could increase the airflow and efficiency of the inlet ducts.

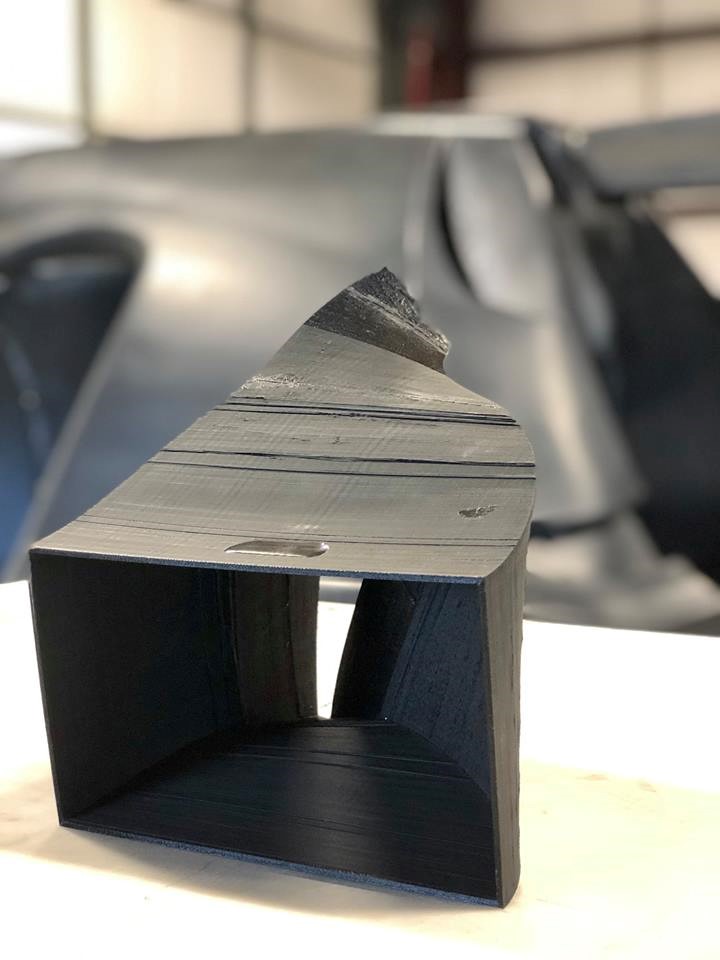

Our on-board engineer, David Nobles, produced the new shape in 3D using our Solidworks program. With that in hand, consultant Larry Hinman was able to 3D print the duct shape (see image below). This duct shape was used as a mold for fiberglass radiator duct parts, and we are now trimming up those parts to make them part of the Switchblade prototype.