Update April 19, 2018

We are setting up to test at a facility north of Prineville, Oregon, called the Oregon Raceway Park.

This race venue is a very nice course set in the rolling hills of Central Oregon. The course is a 2.3 mile dedicated road course, with nice turns and change of elevation. Just the thing to try out a new transmission system! We are excited to use this facility, and see what our newly designed flying car transmission system will do! See an aerial image of a portion of the course above.

Our engineering is speeding up along with the build process, and one of the things we have been finalizing is the rear suspension. Earlier we had successfully tested a torsion rod suspension system, which performed very nicely. We have since changed to nitrogen spring shocks, to be able to capture more energy during hard landings, and absorb more road noise while driving. The front suspension system was tested earlier to certified aircraft standards, and the rear suspension will be tested the same way.

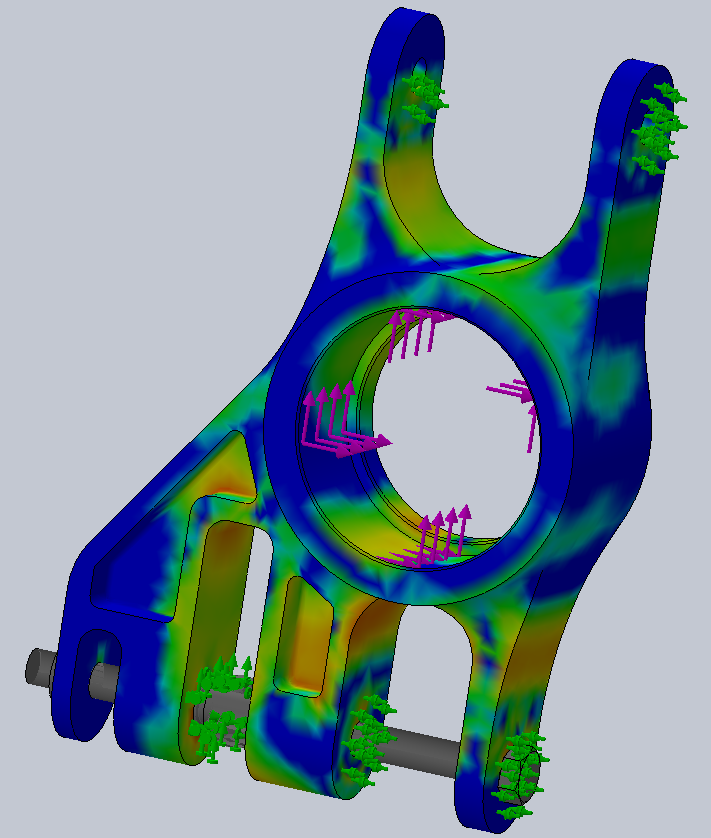

One of these parts is the rear knuckle (funny name for a part that holds the wheel hub and bearings). This part is shown in an engineering screenshot below, and we hope you can see the level of engineering being applied to the individual components. This type of analysis is called FEA for Finite Element Analysis (method of finding what stress a part will be subject to, and how one might be able to change the part to make it a stronger and lighter part). In this case, blue is very low stress, and red is high stress for a given material choice in this part shape. We are approaching a very nice design with this, and it will then be sent to the machinists to make into the two rear knuckles for testing in the flying prototype. We will test on the ground first, of course. Lucky test driver!