We finished the flaps, which are the larger of the two movable main wing surfaces. The flaps are like brakes to an airplane. Those things are like mini wings! Very large, and sturdily built. Above left you can see the skins going into the oven, and above right the finished product after assembly. Although they are nearly seven feet long, they still only weigh 5.6 pounds each, which is incredibly light. We will mount them to the main wing with hinges, and then when the connections are done and hinging working well, we will glue on the top skin to seal the flap.

The wing skins are being carved now, and in two weeks we should see the first of the main wing parts coming out of the oven. The first of the wing skin molds is shown above. The main wings are a little over ten feet long each, so the molds are being made in two parts which are then bonded together and laid on a custom steel table to keep the molds flat. The table has to be built completely flat, and that may sound easy, but it takes a bit of time and skill to make it happen. The temporary molding is quite heavy, being made of wood. The final molds will be of carbon fiber with metal framework to keep them straight in the heat of the oven. That kind of mold is bulky but fairly light.

We presented at AirVenture in Oshkosh, Wisconsin last week. Although a minimal booth and staff (we are keeping our attention on building the prototype), the Switchblade was quite a hit and our booth and Forum presentation were well attended. The booth was one of the most sought after in our area, and constantly gathering questions and interest. It was great to connect up with old friends – who are very excited about how close we are getting to having a full scale flying prototype – and we made hundreds of new friends who are now following our progress and staying in the loop! We displayed the 1/4 scale wind tunnel model, and had an action packed video running which highlighted our recent milestones.

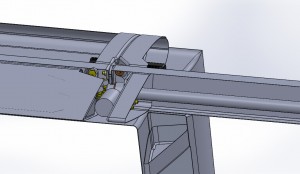

Much work was accomplished on the tail engineering prior to molds. You can see from the image above the construction of the hinged elevators. The elevators are the horizontal stabilizer (wing) parts that move to pitch the nose up and down. The horizontal stabilizer (along with the elevators) are hinged to fold out of the way for ground mode. There was concentrated engineering work done to ensure that the hinging and locking mechanisms work with minimal complexity and maximum accessibility so they can be easily maintained. You are seeing the joint with the top skins off between the elevator to the left, and the vertical to the bottom.