Update 30 October, 2017

We sent more samples out for test coatings of the Black-T material, as the first tests showed incomplete coating in part holes. Black-T is a very thin, military-like coating that can be bonded to metal to protect the metal from the elements, and in our case, from conducting electricity. The second set of coatings showed the same thing, and it was found to be a quality control item at the coating shop, rather than the material. The Black-T seems to work just fine to prevent the flow of electricity from Carbon to the metal parts. In the image below, this aluminum part was coated with Black-T and then tested for whether it could pass current or not. The outside shapes were coated well and did not pass current. The insides of the holes were not coated well, and could pass current. Our take-away here is that the coating is fine if applied well, and not fine if not applied correctly. The next phase is to get a coating company that can provide correctly coated parts, and line them up for coating all metal parts prior to installation.

Why we are bothering about this, is that carbon fibers conduct electricity, and if you have electricity going through the structure with aluminum and steel parts, some of the metals will start to corrode quickly. Boats suffer the same problem, and their solution is to provide a sacrificial piece of replaceable metal that is the location where the corrosion can ‘happen’, and while that metal corrodes and disappears, the rest of the metals remain intact. That piece is replaced before it completely disappears to prevent corrosion elsewhere.

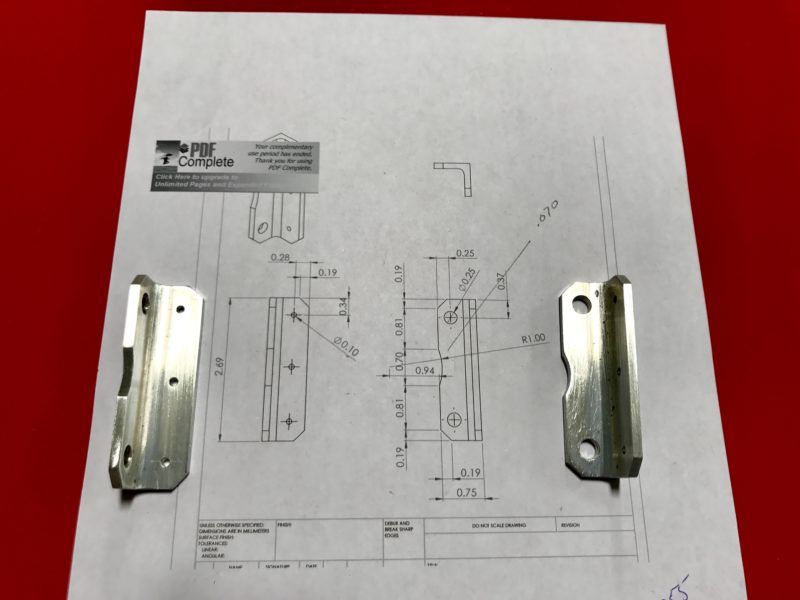

We finished more parts for the tail. Six brackets like the two shown were completed in-house at Samson while the machine shops are working on producing the over 40 other metal parts for the Switchblade tail. The tail contains an almost unbelievable amount of metal pieces due to the articulating nature of the tail. Normally, all of this would be carbon fiber, but the tail swings up and locks in place, requiring metal hinges, brackets, locking mechanisms, and more. You can see the brackets and the print that was utilized to make the parts in the image below.

More work was done on the side door windows, with Sam Bousfield shown below reviewing the fit of the rear glass glide with the Switchblade door glass. The glass glide keeps the window movement in the arc of the glass itself, and there is a front and a rear glass glide. This is important so that the glass doesn’t bind up somewhere along the way, in or out, and break. Door glass is made to be broken in case of an accident or to get out of a car when the door is jammed shut due to collision. The door glass is different from front windshield material, and is designed to break into hundreds of small bits of glass. In an accident, this allows for the occupant to crawl out of the door window opening more safely. Care has to be taken to ensure that the door glass doesn’t break when it isn’t supposed to.

We also started checking locations for the flap switch and the trim switch – both significant controls for the wings. These two switches need to be located where they can be controlled by the pilot easily during take-off and landing. Both switches are used extensively during these times. During landing and take-off, a pilot’s hands should be on the control wheel or stick, and the throttle. The obvious locations for the switches, then, would be the same two places. So far, we are not sure that both switches could be located on the hand throttle (our first choice location). It appears that one will be on the hand throttle, and one on the control wheel/steering wheel. You can see in the image below how the top of the hand throttle looks like with a commonly used Flap Switch located there in easy thumb reach. We are looking at other designs that will better fit the location and intended operation.