Famed Supercar Blondie says the Samson Sky Switchblade is a flying car that’s faster than most supercars.

Famed Supercar Blondie says the Samson Sky Switchblade is a flying car that’s faster than most supercars.

Experience the latest Switchblade milestones, including Sam Bousfield’s Global Innovator Award, major international partnerships, engineering progress, airshow highlights, and a special Founder Edition offer in the December 2025 Samson Sky newsletter.

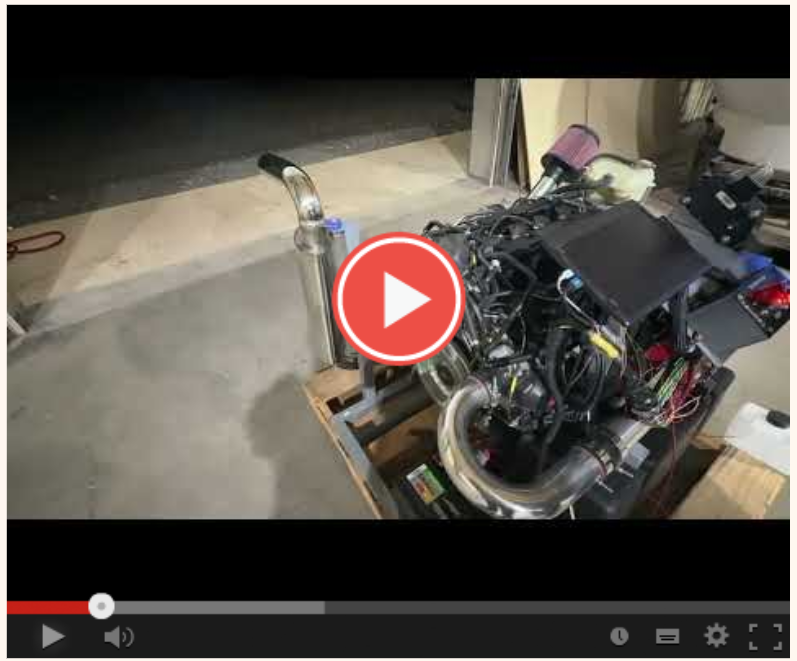

Yes! We started the new hybrid engine on the test stand as the next step on testing and perfecting the electric hybrid transmission system we call Skybrid™. This is with the actual engine we will be using in production, and this engine will likely be used in the first production vehicle.

Sam Bousfield, CEO Samson Sky speaks at the Dubai World Congress for Self-Driving Transport, among 85 of the world’s decision makers who are playing a role in shaping the future of how people move.

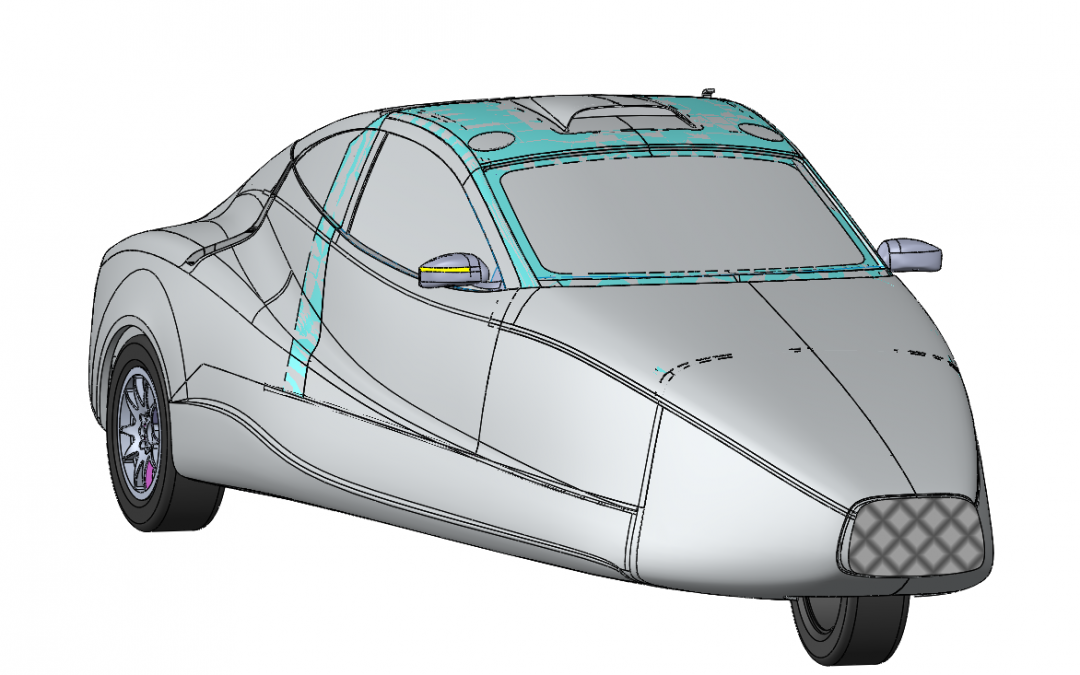

Samson Sky held our annual VIP dinner for Owners and Investors at AirVenture and during the briefing, it was released that the engineering team had been hard at work to reduce the empty weight of the vehicle to allow for a higher useful load.

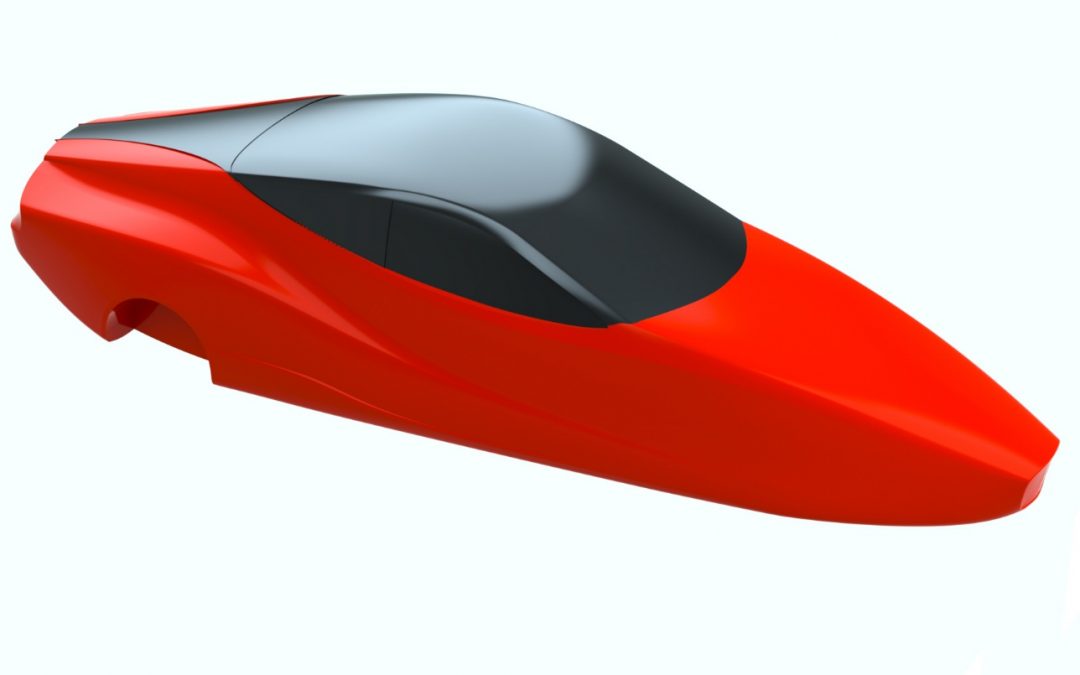

The next parts being made are the front quarter panels on the left and right side of the nose of the vehicle. With this, we should have a completed nose cone as the first completed sub-assembly for the Switchblade.

Faster progress is being made towards Switchblade production, now that bigger funding is arriving.

Here you can see how the team works this test sequence.