Faster progress is being made towards Switchblade production, now that bigger funding is arriving. The larger financial assistance is greatly speeding up the building of our first production vehicle. We are now able to schedule an additional 20 molds and 26 parts for completion at Composite Approach in Redmond, Oregon.

“Conditions are green and we are go for a launch!”

Sam Bousfield

CEO & Founder

Bigger success in fundraising!

Faster progress is being made towards Switchblade production, now that bigger funding is arriving. The larger financial assistance is greatly speeding up the building of our first production vehicle. We are now able to schedule an additional 20 molds and 26 parts for completion at Composite Approach in Redmond, Oregon.

Our overall program is being sped up in another way. The hybrid electric system was the long pole in the tent for flight testing the first production Switchblade. We can now separate off that hybrid system development and allow the progress to continue while we use a battery powered version to gain an earlier flight test of the production vehicle.

Once we validate the hybrid system on the ground, we can replace the battery system with the hybrid system and test that in an already flight-tested airframe that has known flight qualities. This will reduce risk and speed up the testing process at the same time.

Side mirrors designed

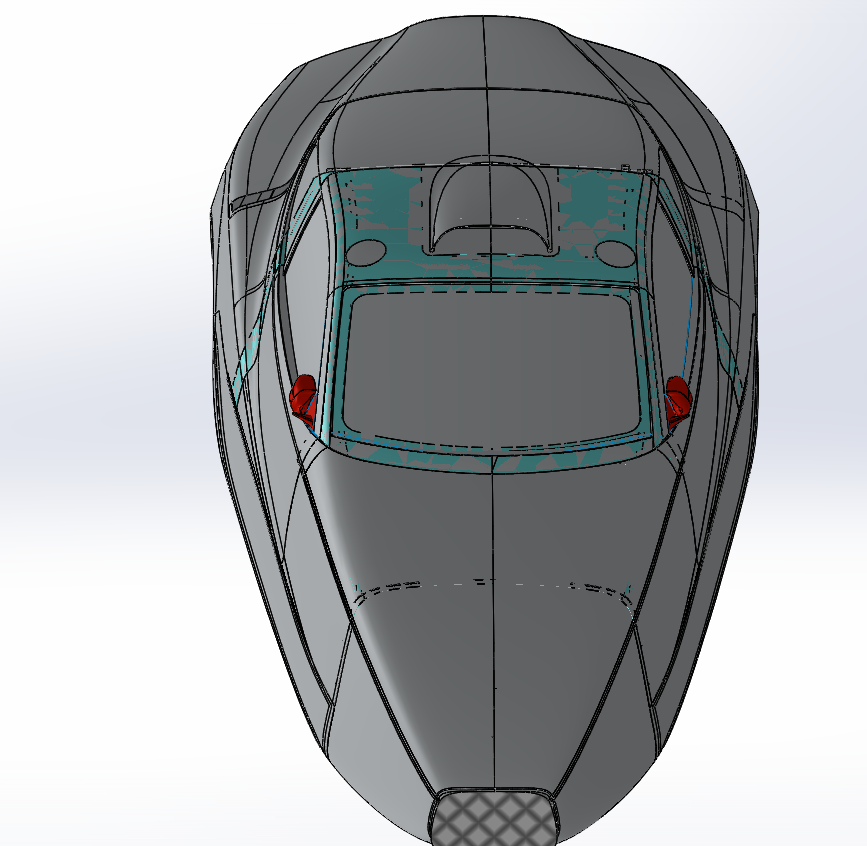

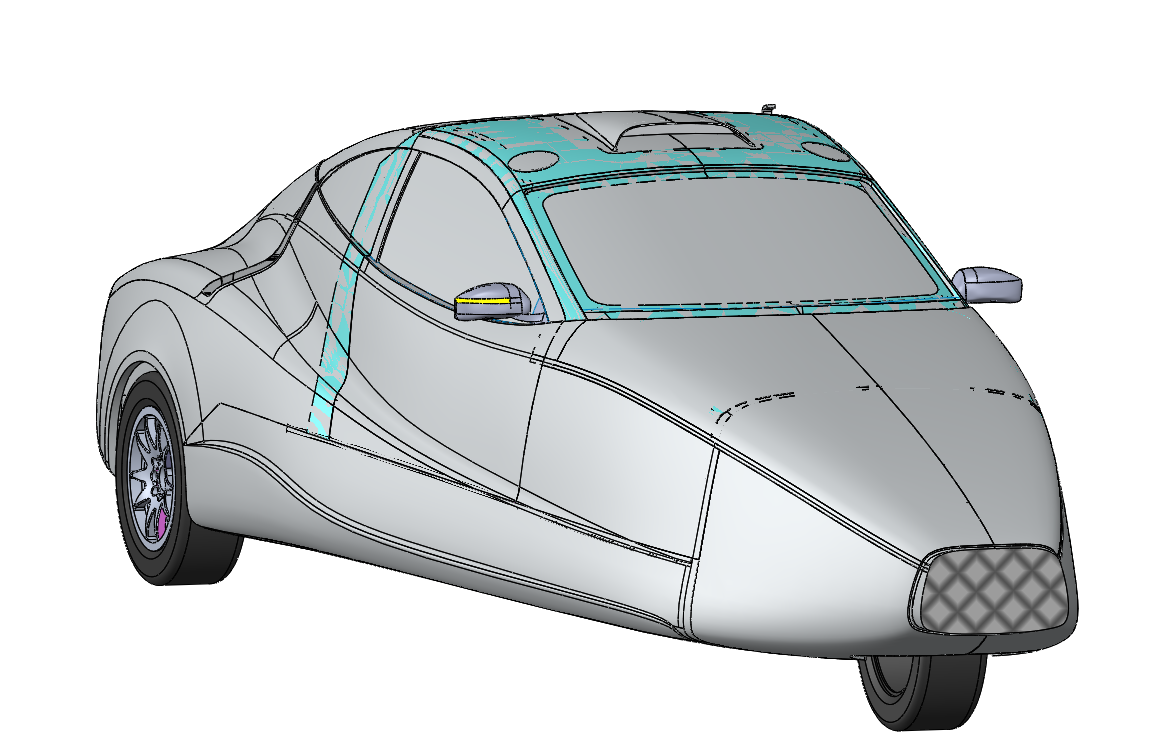

Our needs for side mirrors were a bit different than most cars. For one thing, it would be better to not have the mirrors extended for flight use. You don’t need them, and they would produce a lot of noise at 160 mph.

Mirrors are an easy thing to produce, so we designed mirrors that can be folded alongside the windows in a fairly tight way to reduce the noise while flying. Normal mirrors stuck out from the body quite a bit when folded and were not designed for aerodynamics in that position. You can see in the images above and below how the mirrors look when folded in and when out for ground mode. These are power mirrors, built similarly to your average automobile. The ovals in the green section of roof are mounting locations for the whole-vehicle parachute straps. These were visible in this snapshot from the engineering computers but will not be visible on the vehicle. The parachute will be one of several options on the Standard Switchblade.

Mirrors extended

Meetings with government agencies

Sam Bousfield (pictured above) recently attended the Tech Connect conference in Austin, Texas. There he met with various government agencies such as NASA, Department of Energy, DARPA, Department of Defense, the Navy, Army, and many others. The purpose was to get to know them personally and show them what we are doing so we can establish if there is support for grant opportunities.

While our capital raise for production funds is going well, having grant funds for the hybrid system (for example) could help us move that part along without having to consume so much private funding. It allows the project to retain more ownership while still getting the work done. The advantage to the government is that there are areas they have that could use our tech, or we can provide vehicles for their use that handle a specific need they have.

The result was very good, and we had someone from one branch of the government contact us on the following Saturday to request a proposal. We now have several proposals in the works.

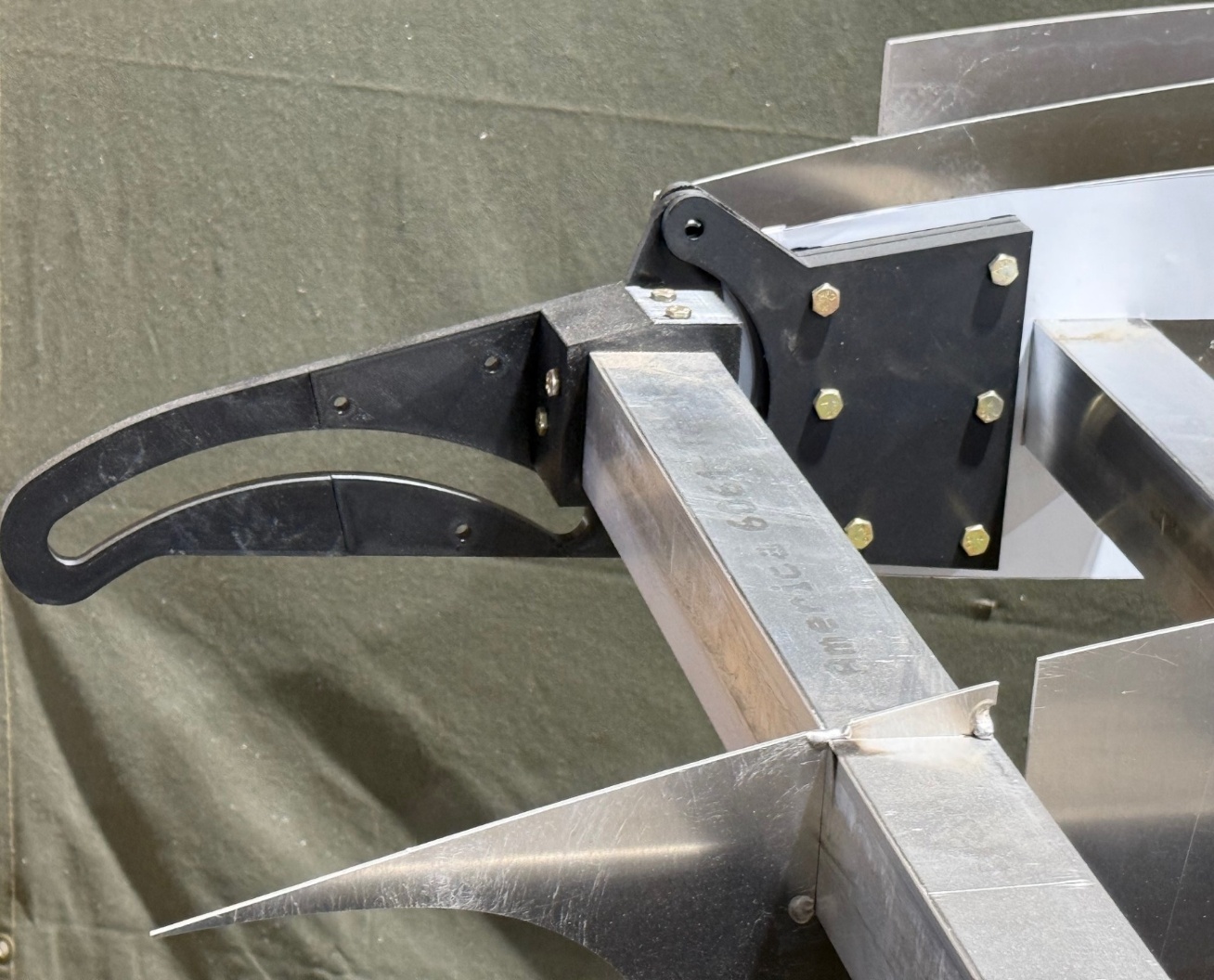

Electric flap mechanism design nearly completed

The Switchblade is designed with electric flaps, like a Cessna 182. Flaps are the moving part of the wing that deploy and make the wing bigger so you can land at a lower speed. The flap mechanism moves the flaps along the curved tracks shown in the image above. This system design has now reached the point where the next step is to create the final parts in the computer and have them made. These parts will join the parts above in the Iron Bird (which is a metal skeleton used to test assemblies in the real world) prior to making the final assembly out of carbon fiber parts. From there we install them into the actual wing and get the wings ready for installation into the vehicle.

Builder Assist Program as game changing strategy

Our most recent press release was picked by an all-time highest ever number of news outlets, reaching a Total Potential Audience of over 243 million! We unveiled our revolutionary Builder Assist Program that is intended to make the Switchblade even more accessible to a huge number of people. Many other Builder Assist Programs typically require customers to invest weeks or even months of work. Samson’s program is a game-changer for Experimental Aircraft as it leverages the benefits of automated manufacturing, simplified tasks, and a one-week Builder Assist Program for customers.

This refined program still allows people to keep within the 51% regulations of the Federal Aviation Administration for our category of aircraft. No special skills are required, and Samson staff are there to train people on the simple steps utilizing automated machines to produce the carbon fiber parts for their Switchblade. While it is extremely easy and fast to do, you learn the process of how to make these parts with computer guided machines and robot assistants. We think it will be the experience of a lifetime, and while it may have been easy for you, it will seem astonishing to your friends.

In the recent articles about our game-changing manufacturing program, I was quoted as saying: “Just having a flying car brings incredible prestige, but being able to say that you built it elevates you to Tony Stark status.”

Maybe you should get your Tony Stark badge and put a $500 Deposit down to gain a fixed delivery position. Deposit

Blue Skies

Sam

CEO/Founder

Switchblade in the News

Check out the latest media about the Switchblade and Samson Sky

Yahoo Finance

Samson Sky Unveils Game-Changing Manufacturing Program for Flying Car

Travel and Tour World – top travel website with an audience of 13+ million/mo. published around the world in numerous languages

Samson Sky’s Flying Car Manufacturing Revolution Slashes Costs & Boosts Speed, What You Need To Know