Here you can see how the team works this test sequence. Ron is in the sim (right) and Sam Bousfield (left) is noting what is working and what is not, as the test pilot flies the simulator.

“If you are a techie, be prepared to geek out!”

Sam Bousfield

CEO & Founder

AI heading for the cockpit

We have built success using AI (Artificial Intelligence) to help the pilot in busy airspace by monitoring the radio and converting speech to text. This was tested by having recorded communications from Air Traffic Control be played back to the AI, which was able to recognize our specific tail number, record the communication, clean up the audio for it, convert it from speech to text, and put the text on a screen for the pilot to read and respond.

This all happens in less than a second, so there is no perceivable delay in the communication. The next step is for the AI co-pilot to recommend a response to ATC, with a button to push to activate that response. For example if ATC sends out a radio message with your tail number and requests a change of frequency (called a hand-off from one ATC staff to another), the AI co-pilot could put that on the screen and recommend a response to broadcast to ATC, such as “change frequency 122.4 155SB” which means you are changing the aircraft radio frequency to 122.4 megahertz and your tail number is 155SB so ATC knows the right person heard and is changing frequency as requested.

A further extension of this would be that the next thing the AI co-pilot does is put the request to the pilot “change frequency to 122.4?” and if the pilot says yes or touches the ‘yes’ on the screen, the AI would change the frequency.

Integrating the AI with the hardware will take some time and cooperation with the avionics manufacturers, so isn’t an overnight change to be made. But it is coming!

Initial flight testing using VR goggles and simulator

Test Pilot Ron McElroy in the VR Simulator

We initially built this plywood cabin mockup to test the ergonomics of the Switchblade, including ease of getting in and out, angle of seat recline, view angles, interior dimensions, etc. We have also been using the plywood cabin mockup for flight simulator testing of various pilot control options, as we finalize the cockpit design. This is a large step and has been going on for months. Above you see Samson Test Pilot Ron McElroy working in the sim to get his feedback on one particular pilot control setup.

We have been testing different setups to see which is the most intuitive and easy way to handle the taxi, take-off, flight, landing, and back to taxi sequence. Different flying cars have handled this in different ways. We had our own way of handling this with the prototype that flew. Now that we are going into production, we are validating those things that we know are still true and sorting out the potentials to find the options that are easier to use.

Team work for sim testing

Above you can see how the team works this test sequence. Ron is in the sim (right) and Sam Bousfield (left) is noting what is working and what is not, as the test pilot flies the simulator. The input is mainly from the test pilot, but an observation of how often the pilot has to adjust his head to see things is something that is noted. Mechanical Engineer Tanner Vaughn (middle) is operating the sim to set up the landing approaches or wind conditions for the test pilot.

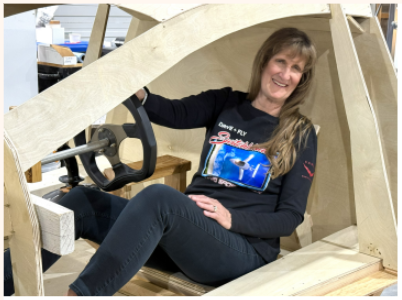

Below, Martha Bousfield gets her turn in the mockup – smiling after completing some vision angle tests conducted by Samson engineer David Nobles.

Wing testing

We have begun testing the wings by building what is called an Iron Bird. This is a term used to describe a mockup of something (like a wing in this instance) using the parts and geometry of the actual thing. For the wing, we have a fold-over mechanism that allows the rear portion of the wing to fold over top and stow within the body of the vehicle. Our Solidworks computer program shows us that we have clearance and that it all works fine, but there are limits to what the computer can simulate and it is often the case that engineers will want to build a test article to validate things before major time and money is invested in making the ‘real’ article.

The image above shows the right wing (as an Iron Bird) sitting on a metal platform. The Iron Bird is built using aluminum structure to speed things along. The real wing will be made from carbon parts produced using production molds and tooling – a much longer process! The hinges are black, and some are 3D printed due to their complexity. Sheet metal ribs establish the shape of the wing so we can spot whether the folded surfaces are indeed not conflicting with any fixed wing surface. The wing back section is currently hand-moved to validate clearance, and then we will actuate the motion using the same actuators as will be used in the real wing to make sure that there isn’t a problem in operation.

The image below is a closeup of the arching flap track. The flaps are extended when landing to slow the aircraft down and allow it to fly at slower speeds more safely when coming in for a landing. In this case the flaps move by following a curved track like you find in many large aircraft (Boeing and Airbus). Some smaller aircraft have the same operation of their flaps, and our system is modeled after what has a proven track record.

We have reached the point where are focusing more attention on the systems inside the carbon skins. This is to ensure that as we make the carbon parts, we have correct locations and amount of reinforcing for stresses that will be placed on the carbon by things like the wing hinges and wing actuators. This all takes place while we continue to build parts and make molds.

The end result will be a production vehicle ready for testing, to allow us to enter production with something we can stand behind for warranty and safety of our customers. The aircraft and pilot community does not tolerate ‘maybe it is good enough’. Our reputation is built by providing an excellent product and a safe vehicle for you. As you may recall, during the build of our first flight prototype we use certified aircraft design standards even though we are not required to as an Experimental Category aircraft. The dream of a flying car is being grounded in engineered safety, including the option of a full-vehicle parachute.

Speaking of dreams, recently our Prineville team was treated to this amazing multiple rainbow. If you look closely, you can see how the colors (especially the purple) repeat themselves. We definitely get some wild weather at our R&D Center.

Blue Skies or Rainbows,

Sam

CEO/Founder

Video Link For Accredited Investors

Samson is inviting like-minded visionaries who have a burning desire to bring the next big thing to the world, better mankind, make a lot of money (lots of zeros), and have fun doing it. We were happy to revise our investment documents, which now more fully describe the size of our business opportunity.

For those who may have looked at investing in Samson before, the game has massively increased, and it is definitely worth taking another look.

Switchblade in the News

Check out the latest media about the Switchblade and Samson Sky

General Aviation News

General Aviation News – Samson Sky