Local Inventor nears launch of Flying Car

The ‘Switchblade’ considering U.S. production facility

For almost 20 years, Sam Bousfield has been tinkering on a project that sounds like science fiction — construction of a flying car that can drive on city streets, take off from small airports and soar to destinations hundreds of miles away.

Now after years of engineering challenges, regulatory negotiations and global travel to meet potential buyers, Bousfield’s company, Samson Sky, says its Switchblade flying vehicle is moving closer to production.

The first of three test vehicles is currently under construction.

In 12 months, production is set to start on vehicles for early adopters, followed by large-scale production.

“In 18 months we should have our three vehicles built and on the road on a 50-city tour,” Bousfield said.

Central Oregon and beyond Although the Switchblade is being developed with an international market in mind, Bousfield has kept research and development in Central Oregon. The company’s R&D operations are based in Redmond, and Bousfield said that location will remain a core part of the program even as production expands elsewhere.

That expansion has recently gained momentum overseas.

Last fall, Bousfield and his team were invited to Saudi Arabia’s Sand & Fun Airshow, one of the largest aviation events in the Middle East and North Africa.

While they displayed only scale models, not a full aircraft, Bousfield said his team enjoyed a positive reception.

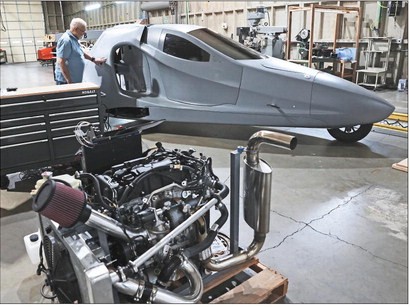

Engineer Dana Beebe with the Switchblade flying vehicle prototype and an inline, 4 cylinder, fuel injected, turbo charged engine that is used in the Switchblade at Samson Sky in Prineville.

(Dean Guernsey/The Bulletin)

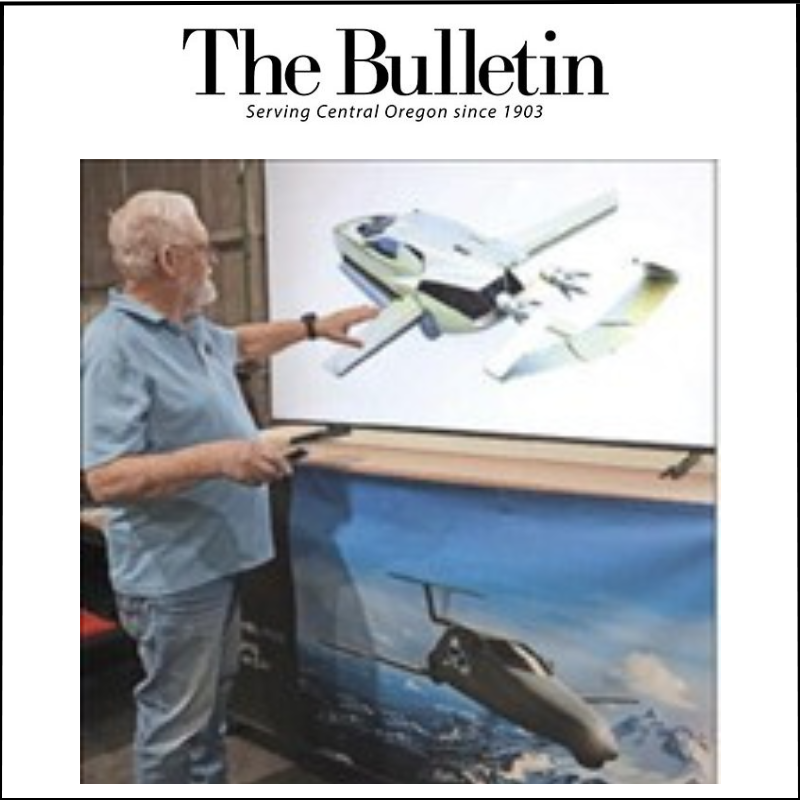

A screen capture of a test flight of the Switchblade flying vehicle prototype at Samson Sky in Prineville. (Dean Guernsey/The Bulletin)

“The Switchblade was very much a hit of that show,” he said.

Members of the Saudi royal family toured the exhibit, and the Switchblade drew enough attention that Saudi Arabia’s National Industrial Development Center later proposed a $90 million grant to establish a regional manufacturing facility in the kingdom.

Saudi officials see personal aviation as an opportunity to expand transportation options in a country with few airports and vast distances between cities, Bousfield said.

“They don’t have the kind of general aviation infrastructure the U.S. has,” he said. “They’re looking for ways to build that.”

India has also emerged as a potential production hub. Discussions with Indian officials revealed financing programs that could cover as much as 75% of the cost of building a manufacturing facility there, according to Bousfield. With severe congestion and a growing population of wealthy consumers, India could become one of the Switchblade’s largest markets.

Advantage Switchblade

The Switchblade is not a vertical takeoff aircraft like many of today’s electric air taxi concepts. Instead, it is designed for regional trips of 200 to 500 miles, cruising at about 160 miles per hour.

“All the electric models are less than 100 miles,” he said. “They’re great for going from a major airport to downtown, but that’s the limit.”

The Switchblade’s wings fold alongside the vehicle, allowing it to drive on roads, park in a standard garage and fit into a regular parking space. The vehicle will have a cruising altitude similar to that of a Cessna, which is typically 8,000 to 13,000 ft.

Bousfield describes it as a solution to trips that are often inefficient by airline — distances long enough to fly, but short enough that airport security, boarding and connections erase the time advantage.

Autonomous option

He gave an example of where the Switchblade could be especially useful in the future — if the vehicle can be autonomous and operate as Waymo does today.

“You say, take me to Chicago and it will come pick you up at the corner and drop you off at the Chicago Symphony after a 500-mile trip. That’s a pretty good service,” said Bousfield. “If you go to the airlines … it’s going to take twice as long as getting there in a Switchblade.”

The Switchblade is expected to be sold as an experimental aircraft, a category that already accounts for roughly 20% of general aviation in the U.S. federal rules require owners to participate in at least 51% of the construction process.

To make that feasible, the company plans a highly automated build system using carbon fiber manufacturing techniques similar to those used by Boeing and Airbus. Owners would spend about a week at a production facility operating machines that fabricate their individual parts, instead of assembling the vehicle over months or years.

U.S. production still first Despite international interest, Bousfield said the first production facility will be in the United States, likely using a leased building to speed up the process. Construction of that facility could begin around 2027, after several prototype vehicles are completed and tested.

The company has received a private investment offer of about $80 million toward the U.S. facility, though additional funding will still be needed. The exact location has not been finalized, but Bousfield said Oregon will continue to play a role in the project.

Once the U.S. operation is running, additional facilities in Saudi Arabia and India would follow later in the decade.

A long road — and runway Bousfield first sketched the idea for the Switchblade in 2008. Before that, he spent 25 years working as an architect while pursuing aviation as a personal passion. Early collaborations with aerospace engineers and a Stanford professor led to advanced aircraft research and several published papers, helping convince him the flying car concept was technically possible.

What has kept him going since, he said, is a mix of obligation and belief.

People have wanted flying cars for decades and decades and decades,” Bousfield said. “I could not, despite hitting lots of hard places along the way, bring myself to give up because I basically promised and gave my word: we’re going to do this.”

The ground test vehicle for the Switchblade flying vehicle at Samson Sky in Prineville.

(Dean Guernsey/The Bulletin)

Engineer Dana Beebe illustrates the transformation process of the 2nd generation hybrid production Switchblade flying vehicle at Samson Sky in Prineville. (Dean Guernsey/The Bulletin)

Engineer Dana Beebe describes the propeller system on a 1/4 scale model of the 2nd generation hybrid production Switchblade flying vehicle at Samson Sky in Prineville. (Dean Guernsey/The Bulletin)

The flight simulator used for training in the Switchblade flying vehicle at Samson Sky in Prineville.

(Dean Guernsey/The Bulletin)

Michael Kohn, Reporter

https://bendbulletin-or.newsmemory.com/?publink=4d1b115f1_1351f41