Samson Sky Unveils New Manufacturing Program

Enables 8x Faster Carbon Fiber Production At Half Cost

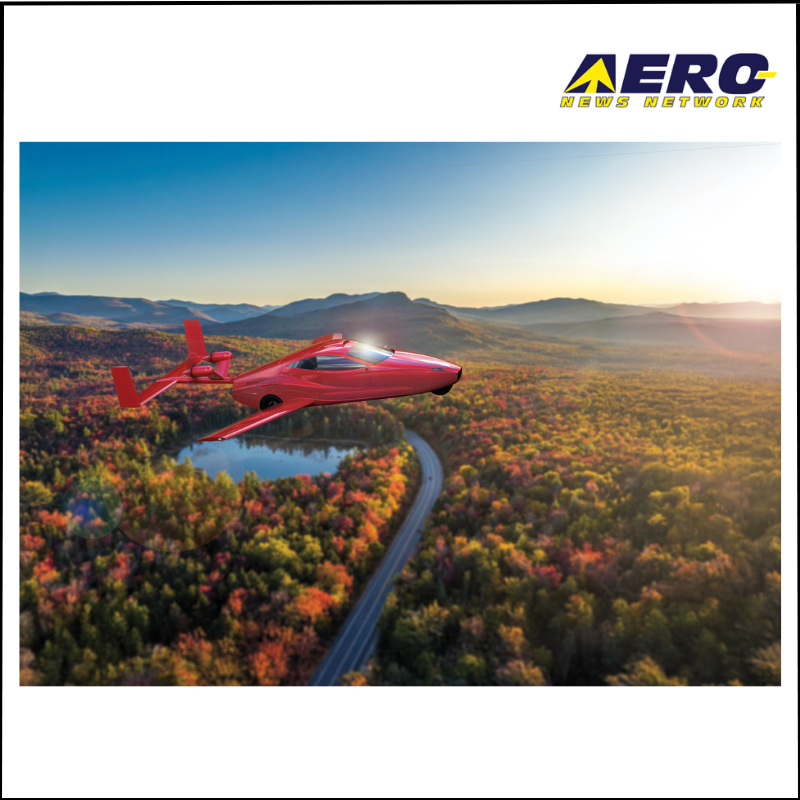

Samson Sky, makers of the Switchblade Flying Car, announced the introduction of its new manufacturing process, which will enable the company to produce carbon fiber parts eight times faster and at half the cost of traditional carbon fiber parts production.

The company says the new process will allow Samson to keep the Switchblade priced competitively.

The centerpiece of the new system is Samson’s Builder Assist Program, which is designed for customers to meet the FAA’s 51% construction requirement for Experimental Category aircraft. Rather than having to learn specialized skills, customers use computer-guided machinery to fabricate their parts. This ensures accuracy and efficiency, and the final assembly is completed by Switchblade technicians to guarantee precision and quality throughout the process.

Switchblade officials said the new program cuts their original projection of the customer’s time commitment from nearly a month down to just one week at the Samson Builder Assist Center.

Sam Bousfield, CEO and designer of the Switchblade said, “Our high-tech system saves owners time and money while giving them the unique experience of building their own vehicle. Part of our purpose is to transform travel while reducing our footprint on the earth. With our system, we’ve created a scalable model for producing high-performance parts with a fraction of the environmental impact of traditional methods.”

Samson says it is preparing for large-scale production, with more than 2,400 reservation holders across more than 50 countries and all U.S. states, the goal is to begin delivering the first Switchblades in 2026.